The Future Of The Manufacturing Industry Lies With Augmented Reality

Since the industrial revolutions, the manufacturing sector has consistently seen improvements that have resulted in high productivity, cost effectiveness, safety of the work environment and profitability. Important innovations during this period include the use of electricity, the production lines, the Bessemer steel process, steam power and the cotton gin. Interestingly, this sector is arguably seeing another revolution in the wake of the 21 century: augmented reality.

Augmented reality turns 27 this year. It was first developed by the U.S. Air Force in 1992. Since then, AR has consistently grown and it is growing into a technology that has become a part in our everyday lives. Pokémon Go, which is a major reference point as regards commercial venture of AR, taught tens of millions of users how to use their phones to interact with virtual objects in the real world.

Beyond the fun and gaming it had been used for, augmented reality is today being used by factories for works because of the many advantages that it brings.

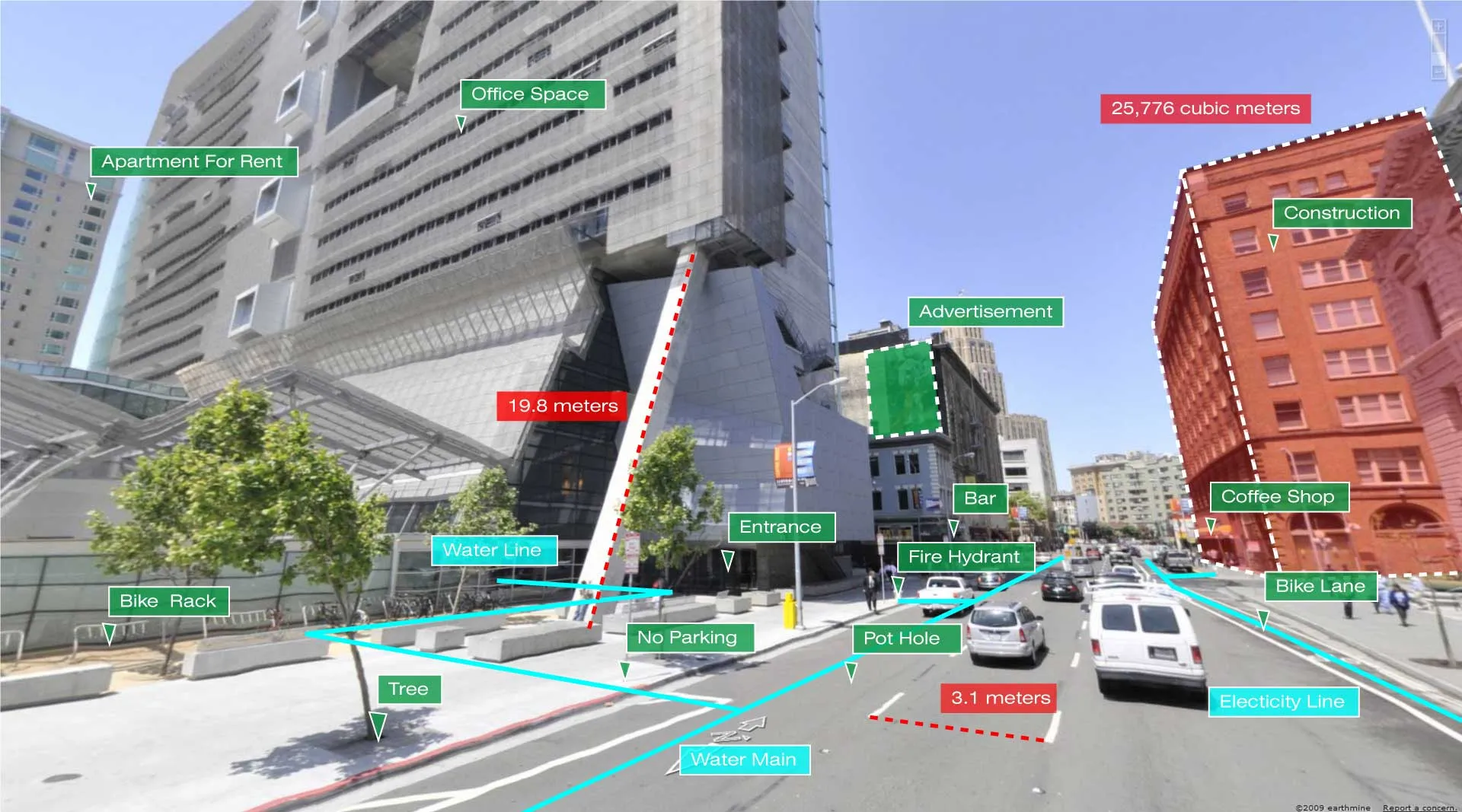

Imagine you are looking through the camera view of your smartphone or tablet and, as you pass your device over objects, graphics, sounds and information appear. That is augmented reality (AR) in action; it superimposes a computer-generated image on a user’s view of the real world, giving the user a composite view.

And rather than having to wear special glasses or a head piece to see this information, augmented reality can operate simply through an app downloaded onto your device. With statistics showing the increased dependence on smartphones and tablets, it is worth considering how this new technology could benefit people, organizations and manufacturing companies all over the world.

Adam Robinson in his article, The Top Five Manufacturing Challenges of 2018 highlighted what he thinks are the major challenges facing the manufacturing industry. Of the five things he listed, we shall discuss four in company of the solution that augmented reality could help in saving the current situation.

Manual handling and safety

Due to the nature of works in manufacturing plants, manufacturing can be a dangerous industry, and it’s vital that manufacturers are aware of health and safety regulations and far more important is their doing something on saving their workforce from harms ways. The Bureau Labor of Statistics reported that in 2017, “there were approximately 2.9 million non-fatal workplace injuries and illnesses reported by private industry employers.”

Of the most frequent non-fatal injuries to employees by most common accidents, larger proportions are linked to lifting and handling. Hence, it is critical for manufacturers to find ways to reduce the risk of injury.

Knowing this, the military uses Augmented Reality (AR) to assist men and women as they make repairs in the field. Medical personnel use Augmented Reality (AR) to prepare for surgery. The manufacturing industry can do the same in order to safeguard her workforce.

Skilled labor shortage

The manufacturing industry faces another major challenge, which is the lack of skilled labor. The Manufacturing Institute and Deloitte Consulting LLP conducted a survey, which showed that 22% of skilled manufacturing workers (almost 2.7 million valued employees) would have retired by 2025 (10 years from the time of the research, which was conducted in 2015).

Consequently, there is an urgency to maintain a steady flow of trained workers in the manufacturing industry. Augmented reality positions itself as a ready solution that can bridge the skill gap.

In practical terms, augmented reality helps build skills in three key areas:

1. Product visualization

With AR, workers have access to product information and diagrams or videos of how to operate machines overlaid on the physical machines. This training method has demonstrated its efficiency in building skills faster and for the long term. Instead of taking many years in training, workers and new hires can train on the job by direct interaction with the actual machines they will use, and they can see instructions on how to assemble specific components. This increases the speed and accuracy of the manufacturing process.

2. Remote Assistance

Augmented reality is very useful for field technicians who need an expert to guide them in repairing a challenging malfunction. This type of remote assistance is also useful in customer service: a technician guides the owner of a product to troubleshoot defects via augmented reality mobile apps.

3. Procedural Guidance

Using augmented reality overlays, workers can learn work procedures, safety precautions and other types of instructions. The information (text, diagram, video) appears floating above the physical item at the precise moment when the worker needs to do (or refrain from doing) something.

The Internet of Things (IoT)

As technologies keep advancing, they drive innovation in various sectors. To stay relevant and keep up with new trends, the manufacturing industry also needs to employ latest technologies. One of such important ones is the Internet of Things. According to Robinson, “the biggest challenge is how best to implement IoT to achieve operational goals such as reducing costs, improving efficiency, increasing safety, supporting compliance or pushing product innovation.”

The combination of IoT and AR can empower organizations to not only gather data and generate actionable insights through a network of sensors, but also deliver those insights to the right people at the right time to create maximum impact.

Maintaining the right inventory levels

In the article, Robinson asserts that inventory challenges are a common occurrence in the manufacturing industry. He suggested that “to help maintain the right inventory levels, manufacturers can use real-time tracking throughout the whole production process. Through serialized barcode, it’s possible to see the location and quantity of goods.”

A good example of how AR can help to mitigate this challenge is through Vision Picking. Vision picking is AR being used in supply chain management. This emerging technology is making strides in warehouse management, allowing for more accurate tracking of items, and it’s easy to see why. Since it improves productivity and accuracy, it is a better way to manage logistics.

Among several other benefits earlier stated, augmented reality doesn’t disrupt the use of existing technology. That is to say, companies can use AR without making major changes to their existing IT infrastructure and machinery. And, cost/benefits ratio is amazing.

As the augmented reality technology seems to offer various solutions to the major challenges in the manufacturing industry, can we say that the future of that sector lies with AR? In that case, it would also be okay to say that the future is already here with us.

Reference:

- https://arpost.co/2019/04/12/augmented-reality-reduce-skill-gap-industrial-sectors/

- https://www.clearspider.com/blog-vision-picking-inventory-management/

- https://www.ducksters.com/history/us_1800s/industrial_revolution.php

- https://cerasis.com/manufacturing-challenges/

- https://arpost.co/2019/04/12/augmented-reality-reduce-skill-gap-industrial-sectors/

- https://medium.com/swlh/5-use-cases-of-augmented-reality-that-boosted-businesses-sales-2114ac35bf5a

- https://www.healthandsafetyhandbook.com.au/using-augmented-reality-for-workplace-safety/

- https://www.bls.gov/news.release/pdf/osh.pdf